Compared with single cylinder dryer with the same specifications, the thermal efficiency is increased by 40%-55%, double times saving energy. Because of the unique structure of multilayer sleeve drying machine, the length of the tube is 1/3, the base area saves 65%. The investment is reduced.

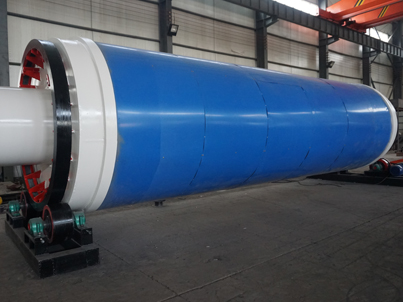

Using the latest European energy saving technology, the three cylinder dryer, combined Inner cylinder, middle cylinder and outer cylinder form a self insulation structure, the three concentric cylinders with different diameters, according to mathematical relations and structural forms. The thermal efficiency of the dryer can be greatly improved with the full use of the waste heat, reducing the lost of heat.

The main application field of three cylinder rotary dryer is to dry the Quartz Sand, Furnace Slag Cement, Granular, Sawdust, Lees, Coal, Fly ash, Dry motar, and so on.

Feature of Triple drum rotary drier

1. Triple drum rotary drier use telescope-feed structure, drying fast.

2. Simple design, self-insulation, improve the heat efficiency to exceed 80%.

3. Using alloy steel plate, wear 3-4 times than ordinary steel plate.

4. The fuel can be coal, oil, natural gas etc, dry mass and granule and powder material.

5. Reduce 50% land occupied compared to single drum rotary dryer, so construction investment is saved 50%, and power consumption saved 60%.

The overall structure of the three cyclinder dryer is made up of three ring-shaped cones welded in different directions and in different sequence. This special structure determines its high efficiency, energy saving, compact structure, less floor space.

reliable work, low energy consumption, high thermal efficiency, good material drying effect, easy to achieve automatic control, and fewer operators.

| Model |

Outer tube diameter |

Outer tube length |

Cylinder speed |

Intake air

temperature |

Power kw |

Weight(t) |

| ï¿ 2.0×5 |

2.0 |

5 |

4-10 |

<850° |

5.5x2 |

22 |

| ï¿ 2.2×8 |

2.0 |

8 |

4-10 |

<850° |

7.5x2 |

26 |

| ï¿ 2.5×6 |

2.5 |

6 |

4-10 |

<850° |

5.5x4 |

27 |

| ï¿ 2.7×6 |

2.5 |

8 |

4-10 |

<850° |

7.5x4 |

29 |

| ï¿ 2.8×6 |

2.8 |

6 |

4-10 |

<850° |

7.5x4 |

30 |

| ï¿ 3.0×7 |

3.0 |

7 |

4-10 |

<850° |

11x4 |

33 |

| ï¿ 3.2×8 |

3.2 |

8 |

4-10 |

<850° |

15x4 |

38 |

| ï¿ 3.6×9 |

3.6 |

8 |

4-10 |

<850° |

18.5x4 |

58 |

| ï¿ 4.0×10 |

4.0 |

10 |

4-10 |

<850° |

22x4 |

72 |

What is the heat source of your stove?

Coal, wood, rice husk, or diesel, or natural gas. And our company is developing the gas stove

Do you have CE and ISO?

Our dryer have past the ISO Certificate and CE.

How to choose you dry equipment?

Kindly inform us moisture before and after drying, type and size of raw material, and hourly capacity for output, that's all.

Which kinds of fuel can I use?

oil, gas, coal, stream, wood, pellet, diesel, etc.

I want to install a drying plant, how can I do that?

After negociation, we supply the whole project service, include with designing, producing, construction, installation, trial operation, etc. All the necessary drawings are supplied by us for you to references.

But if the dryer is stop to run with some problem, whatshould I do?

First please do not worry, after-sales service 24 hrs on line to help you. Almost all problems will be settled by video call, telephone, email, etc. If can not, we will fast send engineer to come to help you.

javascript:;

Demand for Online Submission

Leave the meassage, FREE download YUFCHINA exclusive buyer's guide, and help you learn more about biomass pellet machine !