BLOG

| Subscribe to our e-mail can be Downloads Free buyer's guide! |

2016-08-12 17:40:31 hits:1075

How long Is the Lifetime for ring die of Wood Pellet Machine?

Any equipment has its lifetime.Reasonable use and maintenance can effectively prolong the lifetime of equipment. As an important accessory in the pelletizing process,how long is the lifetime for the ring die of wood pellet machine? How to maintenance the ring die?

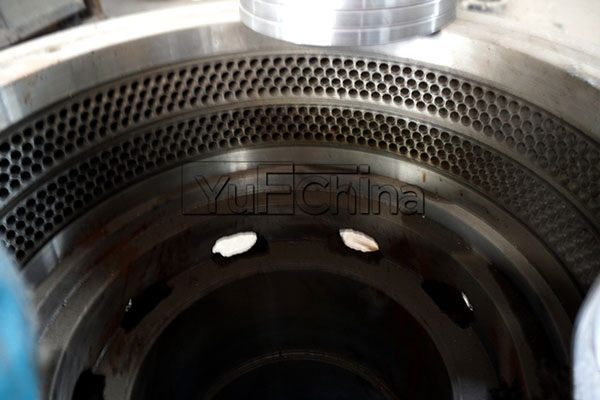

The ring die of wood pellet machine is a porous and ring-shaped vulnerable part. The die wall is thin and densely covered with die holes .The assembly size is with high accuracy.When working,under the press of rotating ring die and roller, raw material is extruded from inner wall to outside through die holes in strips.And then cut knife will cut pellets into needed length.

Surely,the ring die quality of wood pellet machine is not the same.Its lifetime is usually measured by the quality of materials it processed.The lifetime of general-quality ring die is around 800-1200 hours,and that of the best-quality ring die is around 1500-1800 hours.This has something to do with the amount of equipment´s cost.But,in the course of daily use,we must pay attention to maintain the ring die of pellet machine,which can prolong its lifetime.

While using wood pellet machine ,how to care and maintain the ring die?