BLOG

| Subscribe to our e-mail can be Downloads Free buyer's guide! |

2016-01-15 13:51:31 hits:786

Why pellet fuel surface is not shiny?

As you know, the quality is very good with pellet fuel surface smooth, shiny. Then pellet fuel surface is roughness, no gloss, why? How to avoid such a phenomenon? We can find a cause in two ways - raw materials and pellet machines.

Raw material moisture is too high

-- If raw material moisture is too high, too much steam will increase the inter-molecular distance, the influence of heat conduction, reducing the molding temperature, crude fiber is not easy to soften, the adhesive force of raw materials decreased.

-- High moisture content also increases the pellets exposed to radial forces, while also increasing power consumption, resulting pellet cracking, rough surface.

-- High moisture not only affect the production rate but also affect the pellet making rate. While heating the steam generated in the process can not be discharged water from the mold, it will greatly shorten the life span of the pellet mill.

-- To solve this problem is to dry the raw material, the raw material moisture should be controlled between 14% -20%.

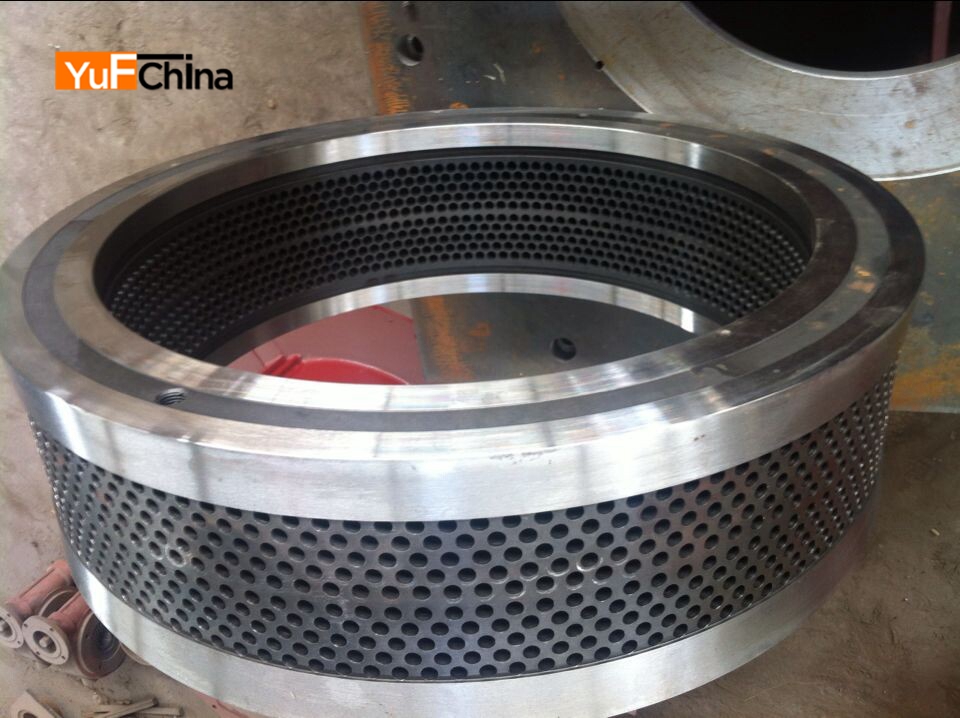

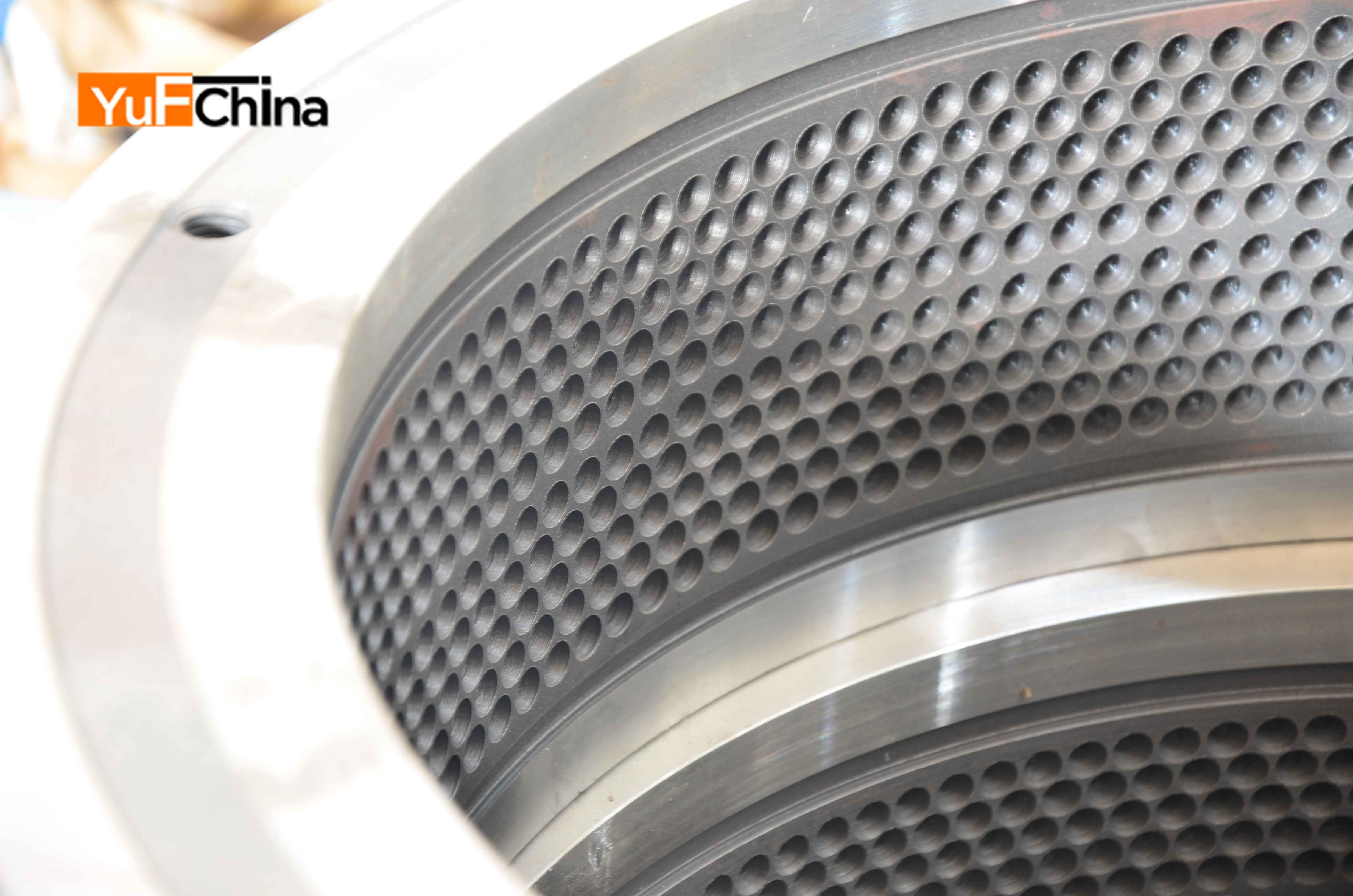

Characteristics of the mold do not match the raw material

Ō¢Č pellet mill die compression ratio

-- Compression ratio is a parameter of the mold particles machine, refers to the ratio of the length of the die orifice aperture. The compression ratio, the more thick template, the longer the material compression of time, the particles forming rate is higher. Mold thickness of less than a certain standard, then, will reduce the quality of the fuel, so that fuel the appearance of loose particles, not shiny, and of varying lengths.

-- This requires raw materials according to their own will find the right compression ratio. The only way to better understand the quality of the particles, improve equipment efficiency.

Ō¢Č gap between the pressure roller and the mold

-- General pressure abrasive wheel and gap control is 0.1 ~ 0.3mm for the best, the gap is too large, the pressure is not sufficient to extrusion. The gap is too small, it may be better in extrude particle density, smoothness, but it will increase the friction wheel mold pressure, reduce abrasive life span, the impact of pellet mill production.

-- Vertical ring die pellet mill clearance adjusting device is fixed above the pressure wheel to adjust the screw through, which requires the use of your materials test machine, find the proper clearance.

PREVIOUS POST

Pellets must be cool before bagging them